Wooden structures for the roof

There are several ways to create a roof truss system made of wood: to make a traditional frame of rafters, posts, struts and braces or use ready-made trusses.

We will calculate the roof according to your individual task and offer the best design option depending on the architecture of the building, the position of the load-bearing walls, the angles of the roof, the type of roofing material.

In addition to the project, we will produce structures for the roof frame. It can be a set of timber for a traditional rafter system or wooden trusses produced at the factory.

Traditional rafter system.

Traditional is called a rafter system consisting of:

Rafter – load-bearing elements that form the plane of the roof slope;

Rack – bearing vertical support elements;

strut – a beam located at an angle between the bearing elements, prevents sagging of rafters and displacement of elements;

In addition to the basic components in the traditional rafter system there are also:

Ridge beam – a beam located horizontally along the ridge of the roof, on which the rafters rest.

Ledgers (purlins) – horizontal bearing element that distributes the load on the racks.

Ties – are used to level the spacer effect in the rafters so that the rafter legs do not “move apart”;

Mauerlat – located along the contour of the walls, is a support for rafters or racks, an optional element if a monolithic reinforcement belt is arranged. In frame houses, the function of the Mauerlat is performed by the strapping beam. A support beam that performs the same function as the mauerlat, but is located on the inner walls is called a lying;

Mare – a bar for the formation of eaves overhang, attached to the edge of the rafter.

Ready-made wooden trusses for the roof.

Wooden trusses are quickly assembled and have a stable structure – these are the advantages due to which ready-made trusses are gradually replacing conventional rafters from the market.

The faster you install the roof frame, the faster you will be able to lay a water barrier and hide the house from precipitation. Also, the acceleration of terms will reduce the cost of labor of installers and travel to the construction site.

Stable construction is the key to beautiful and smooth surfaces, and their preservation over time. A properly designed truss will retain its shape even under significant external loads such as heavy wet snow and will not sag unlike simple rafters.

Why roof truss structures of roofs and attics on MTP are becoming increasingly popular? Choosing a roof project is not an easy task. Especially if there is a desire not only to protect the dwelling and give it a finished look, but also to add an original zest to a country house or cottage. However, as a rule, the more original and beautiful (and hence more complex the project), the more costs are required to ensure its functionality and reliability, and the longer it takes to build.

To eliminate these shortcomings, new types of roof frames were invented – truss structures connected by metal toothed plates (MTP). With their help it is possible to erect reliable roofs of any complexity in the shortest possible time. This technology turned out to be a real breakthrough, and since the 60s of the last century it has spread all over the world.

For the population of our country – it is a novelty, so the specialists of the company PRAGMA recommend to get acquainted with its advantages.

What is the difference between the new technology and why it can be trusted?

Rafter structures are made of planed timber and wood grade, pre-treated with bio-protective agent. MTP are made of steel, up to 2.5 mm thick. With their help, wooden beams and timber are sewn together several times more reliably than with nails or screws. MPZ prevent slipping – and as a result, the structure can withstand a large torsional load.

The design of a modern roof is carried out using computer programs, so the truss structures on the MTP:

- allow you to create trusses of completely different geometric shapes and combine them in one project;

- make it possible to make significant spans between the beams (up to 30 m), which facilitates the weight of the entire structure;

- have high performance and long service life;

- are characterized by simplicity, accuracy and speed of installation.

An additional advantage is the ability to assemble the roof from blocks previously assembled at the factory, each of which weighs no more than 80 kg. This allows you to save on renting a crane, which is not needed in such conditions.

What types of structures can be made on the MTP?

In our area, where snow falls in winter, it is most advisable to use pitched roofs, since precipitation is less retained on them. Let’s briefly consider the most popular types of them.

Pitched roof. This is the simplest and most economical option. It is often used for cottages.

Gable roof. Proven and inexpensive type with high-quality self-cleaning ability and the ability to arrange a balcony on the front or side. The shape of such a roof can be symmetrical and asymmetrical.

Hip roof. It is in high demand because it looks harmonious, neat and more modern.

Multi-gable roofs. These are more complex structures, sometimes with several levels. Perfectly decorate mansions, elite country houses.

Roof with an attic.

You can fit an attic into almost any roof, and with Mitek constructions, you can design a full-fledged storage room, immediately with floor joists, and with a lattice for wall construction. Such an attic will be convenient to sheathe directly on the structures, as the sheathing can be attached directly to the tree.

The type of farm itself in this case is called “attic”. The photo shows the principle of its device: it is an integral structure, in which there is a “frame” for the future room. The difference between an attic truss and an attic truss is usually the height to the ceiling. The attic does not have to be full-sized. A height of 1.7 m may be enough for storing things.

Roof design features

Nowadays, no one builds housing on their own or with the involvement of folk craftsmen, jacks of all trades. To obtain an impressive result requires special knowledge and unique skills, modern industrial equipment and advanced technologies, including software.

In order to achieve high quality, it is also necessary to use environmentally friendly materials. That is why PRAGMA uses wooden trusses on metal-toothed plates. We have installed a huge number of truss systems using certified technology and MiTek products for various roofs, including the most complex ones. The most interesting projects you can see in our portfolio.

Before starting the roof construction, we take into account:

- size, slope and configuration of the roof;

- ventilation outlets, chimneys and other elements;

- the proportion of structural and roofing materials;

- climatic and other conditions in accordance with state building standards (SBS).

To take into account all the nuances of a quality project, you need a whole technical department. That is why PRAGMA company has a department with engineers – high-level professionals.

Why is it profitable to cooperate with PRAGMA?

Our company is ready to be responsible for a high result, so it gives a 10-year warranty on frame structures. But they can last much longer – more than 50 years, subject to proper operation.

What you get by contacting our company:

- We make a project in accordance with the state building codes of Ukraine (DBN). This is a guarantee that in the future, after the completion of construction, the object will be accepted by the relevant services.

- We develop projects using special computer programs. Therefore, any mistakes are excluded. According to the finished drawings, our masters will quickly and efficiently perform the work. After its completion you will get a roof that will serve reliably and for a long time, as well as have a neat, modern and aesthetic appearance.

- PRAGMA company has advanced technologies, has the necessary equipment, uses natural environmentally friendly materials. This guarantees not only comfort but also safety for the residents.

- We entrust the installation of the rafter system only to conscientious employees who know their job and are responsible for the flawlessness of its implementation.

- Our technical capabilities allow us to create projects of any complexity and for any requests.

This means: if you have a limited budget – we will guide you how to save money; if you need exclusivity – we will find something to surprise you.

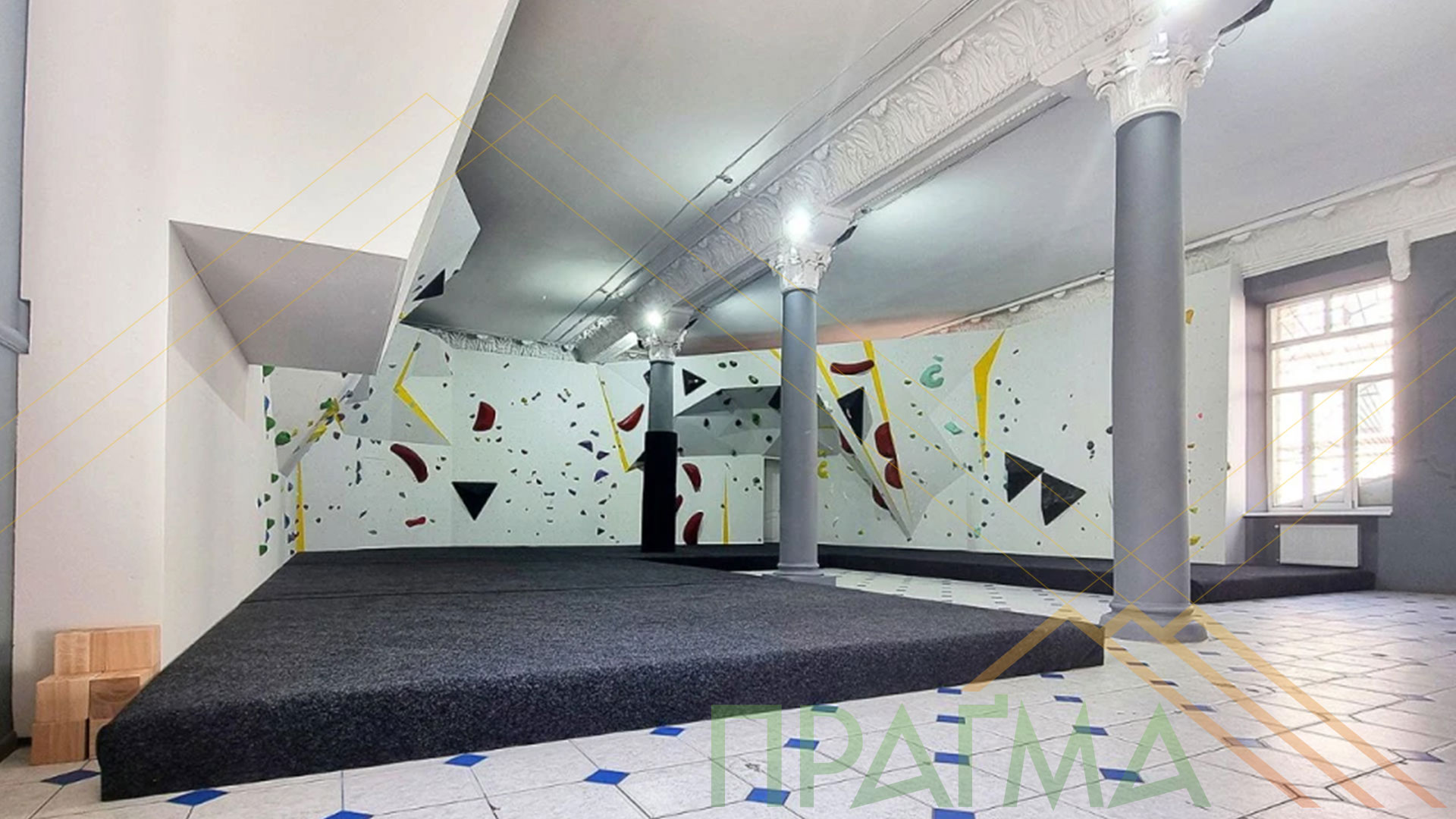

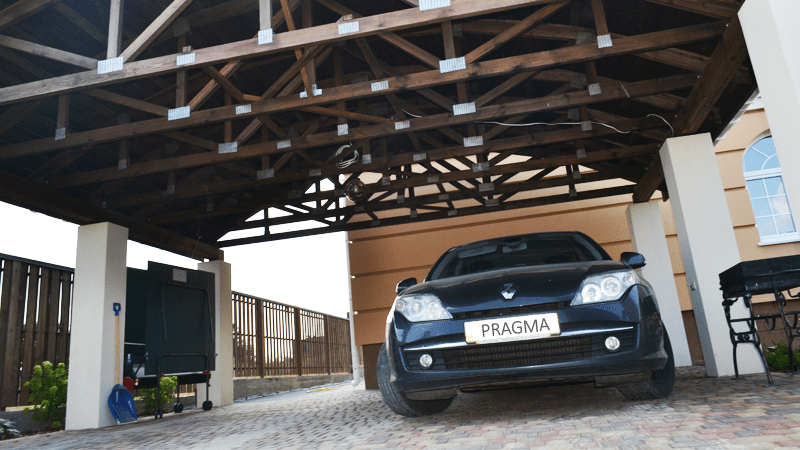

Examples of our works: