Wooden structures for the construction and reconstruction of pigsties

Agriculture, in particular pig breeding, is actively developing, and more and more pig entrepreneurs are thinking about expanding their own production. Therefore, the issues of reconstruction and restoration of old pigsties and the construction of modern pig farms are becoming relevant.

Below we will consider the use of wooden structures in the reconstruction or new construction of agricultural buildings.

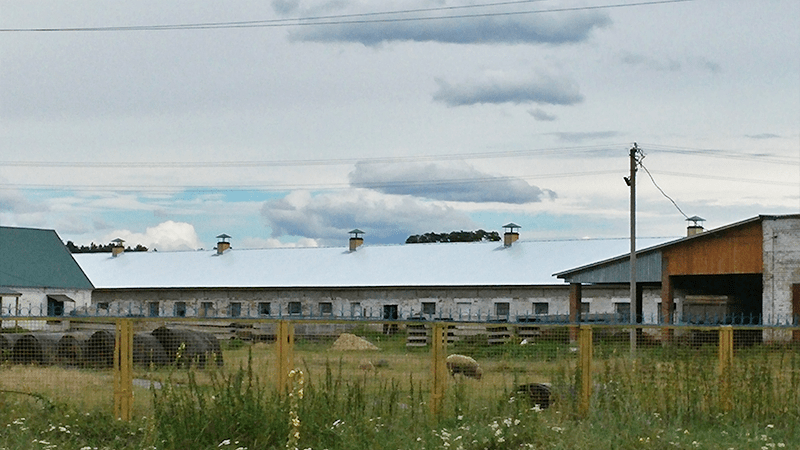

Reconstruction and restoration of old pigsties

The main problem in the reconstruction of old pigsties is the need to replace the old roof frame. Since the reconstruction must be carried out in a short time, so as not to stop the production cycle of growing pigs for a long time, quickly assembled structures are used. Such structures include wooden truss farms. The small weight of a wooden truss (about 120 kg with a length of 12 m) allows it to be used on old walls without taking measures to strengthen foundations and enclosing structures.

A significant advantage of using a long-span wooden truss is the possibility of creating a free layout inside the room, you can remove the internal supports or expand the building and support the structure on the outer walls. MiTek wooden trusses can cover spans up to 30 m.

The farm has a flat horizontal belt, which is easy to insulate and hem the ceiling. A horizontal ceiling will reduce the internal volume of the room, and thus reduce the amount of air that needs to be heated in the cold season. The diagram below shows the difference between the volumes more clearly.

With a horizontal ceiling, the distribution of air masses occurs more naturally than with an inclined one. Warm air is closer to the animals, does not accumulate under the ceiling – this is another plus to the energy efficiency of the building.

Fig.4 The volume of air that needs to be heated in winter:

V1 – In case of horizontal ceiling.

V2 – In the case of a sloping ceiling.

The use of wood in the construction of modern pig farms

Domestic pork producers adopt the experience of management from foreign companies and use in their complexes those principles of construction that have proven to be the most profitable. In Poland, the Czech Republic, Germany and other European countries, from which our farmers take an example, wood is widely used. It is a convenient building material with excellent performance characteristics, and also belongs to renewable resources. Therefore, when creating modern pigsties in Ukraine, effective methods of prefabricated wooden structures are being introduced, and metal or reinforced concrete elements of the roof frame are used less and less often.

Features of insulation in modern pig farms

The principle of insulation depends on the chosen method of ventilation of the building. Based on our own experience and the experience of our partners (BigDutchman and Hogslat technologists), the roof is mainly insulated only along the ceiling, as the inflow of fresh air into the room goes through the wall valves. But there are several examples among our works, where clean air enters the room from the under-roof space through the perforated ceiling or ceiling valves, so the entire roof space is insulated there, creating a kind of recuperation system. See more details on the model:

Hinging.

On wooden trusses it is convenient to attach any hem. This is facilitated by a small distance between the structures, in which there is no need to put purlins, rails, or other intermediate supporting elements. And the material itself is easy to process, and therefore you can immediately screw screws into it, without wasting time drilling holes and searching for the necessary fasteners.

Low thermal conductivity of wood.

Another serious advantage we consider is the low thermal conductivity of wood. It is a good thermal insulation material. The insulation is placed between the trusses, and there is no need to hide the structure itself under the insulation layer.

Fig.7 Insulation between wooden trusses.

The right approach

Any structure in a modern building for keeping animals requires an engineering approach to design and construction. In particular, wooden truss structures for pigsties are calculated taking into account all loads on the roof, which ensures their reliability and durability. Wooden blanks undergo fire and bioprotective treatment with modern means that are safe for humans and animals. Trusses are manufactured in production and undergo quality control of finished structures. Truss trusses arrive at the facility ready for quick installation, this feature allows you to mount the frame in almost any weather at any time of the year.

The undeniable advantages of wooden trusses:

– Wooden structures last longer. Steel untreated by hot-dip galvanizing is quickly destroyed by ammonia fumes, while wood, on the contrary, gains additional strength from them.

– Ease of installation of equipment. Due to the fact that wooden trusses are mounted in smaller increments than metal structures, it is easy to install ventilation and lighting equipment in them. Wooden trusses are usually designed with a pitch of about 1.2m.

– Wood maintains an ideal microclimate. In order for the animals to feel better and have a strong immunity, you need to take care of the excellent conditions of their detention. Wood, as an environmentally friendly material, is perfect for these purposes. It does not form condensation, and it maintains the optimum temperature at any time of the year. Therefore, it is always more comfortable to be in rooms with a wooden roof.

That will convince you of the quality of the manufactured structures:

– Pragma uses only wood that meets Mitek quality standards;

– Design is performed by a certified engineer using licensed Pamir software;

– Manufacturing of structures is carried out according to Mitek technology and equipment.

In addition to the design and manufacture of wooden trusses, we offer delivery of finished products to the construction site, which we carry out throughout Ukraine. Each order is accompanied by free engineering consultations and site visits.

Examples of our works: